Схемы > Аудио > 300Вт УМЗЧ для сабвуфера

300Вт УМЗЧ для сабвуфераRod Elliott (ESP)

Introduction

High power amps are not too common as projects,

since they are by their nature normally difficult to build, and are expensive.

A small error during assembly means that you start again - this can get very

costly. I recommend that you use the PCB for this amplifier, as it will save

you much grief. This is not an amp for beginners working with Veroboard!

The amplifier can be assembled by a reasonably

experienced hobbyist in about three hours. The metalwork will take somewhat

longer, and this is especially true for the high continuous power variant. Even

so, it is simple to build, compact, relatively inexpensive, and provides a level

of performance that will satisfy most requirements.

WARNINGS:

- This amplifier is not trivial, despite its

small size and apparent simplicity. The total DC is over 110V, and can kill

you.

- The power dissipated is such that great care

is needed with transistor mounting.

- The S300 is intended for intermittent duty

on 4 Ohm loads, as will normally be found in a subwoofer. It is NOT intended

for PA or any other continuous duty, and although it may work fine for may

years, I absolutely do not recommend this.

- For continuous duty, do not use less than 8

Ohms.

- There is NO

SHORT CIRCUIT PROTECTION. The amp is designed to be

used within a subwoofer enclosure, so this has not been included. A short on

the output will almost certainly destroy the amplifier.

DO NOT ATTEMPT THIS AMPLIFIER AS YOUR FIRST

PROJECT

Description

Please note that this amp is

NOT designed for continuous high power

into 4 Ohms. It is designed for intermittent duty, suitable for an equalised

subwoofer system (for example using the ELF principle - see the Project Page for

the info on this circuit). Where continuous high power is required, another 4

output transistors are needed, wired in the same way as Q9, Q10, Q11 and Q12,

and using 0.1 ohm emitter resistors.

Continuous power into 8 ohms is typically over

150W, and it can be used in the form shown at full power into an 8 ohm load all

day, every day. The additional transistors are only needed if you want to do

the same thing into 4 ohms!

The circuit is shown in Figure

1, and it is a reasonably conventional design. Connections are provided for the

Internal SIM (published elsewhere on the Project Pages), and filtering is

provided for RF protection (R1, C2). The input is via a 4.7uF bipolar cap, as

this provides lots of capacitance in a small size. Because of the impedance,

little or no degradation of sound will be apparent. A polyester cap may be used

if you prefer - 1uF with the nominal 22k input impedance will give a -3dB

frequency of 7.2Hz, which is quite low enough for any sub.

Figure 1 - Basic Amplifier Schematic

The input stage is a conventional long-tailed

pair, and uses a current sink (Q1) in the emitter circuit. I elected to use a

current sink here to ensure that the amp would stabilise quickly upon

application (and removal) of power, to eliminate the dreaded turn on "thump".

The amp is actually at reasonably stable operating conditions with as little as

+/-5 volts! Note also that there are connections for the SIM (Sound Impairment

Monitor), which will indicate clipping better than any conventional clipping

indicator circuit. See the Project Pages for details on making a SIM circuit.

The Class-A driver is again conventional, and

uses a Miller stabilisation cap. This component should be either a 500V ceramic

or a polystyrene device for best linearity. The collector load uses the

bootstrap principle rather than an active current sink, as this is cheaper and

very reliable (besides, I like the bootstrap principle :-)

| |

All three driver transistors must be on a

heatsink, and D2 and D3 should be in good thermal contact with the driver

heatsink. Neglect to do this and the result will be thermal runaway, and

the amp will fail. |

It is in the output stage that the power

capability of this amp is revealed. The main output is similar to many of my

other designs, but with a higher value than normal for the "emitter" resistors

(R16, R17). The voltage across these resistors is then used to provide base

current for the main output devices, which operate in full Class-B. In some

respects, this is a "poor-man's" version of the famous Quad "current dumping"

circuit, but without the refinements.

Although I have shown 2SC3856 and 2SA1492

output transistors, most constructors will find that these are not as easy to

get as they should be. The alternatives are MJL21193 / MJL21194 or 2SC3281 /

2SA1302 respectively.

Use a standard green LED (do not use high

brightness or other colours) - this may be a miniature type if desired. The

resistors are all 1/4W (preferably metal film), except for R10, R11 and R22,

which are 1W carbon film types. All low value resistors (1 ohm and 0.1 ohm) are

5W wirewound types.

Because this amp operates in "pure" Class-B

(something of a contradiction of terms, I think), the high frequency distortion

will be relatively high, and is unsuited to high power hi-fi. At the low

frequency end of the spectrum, there is lots of negative feedback, and

distortion is actually rather good, at about 0.04% up to 1kHz.

Power output into 4 ohms is over 250W

continuous, and for transients exceeds 300W easily. Use of a big power

transformer and massive filter caps will allow the amp to deliver close to 350W

continuous, but if you really want to use it like that, I very strongly

recommend the additional output transistors (see above comments on this topic).

Power Dissipation Considerations

I have made a lot of noise about not using this amp for continuous duty into 4

ohms without the extra transistors. A quick calculation reveals that at the

worst case, the output and transistor voltage will be the same - i.e. at 28V.

With 28V, load (and transistor) current is 7A, so the instantaneous dissipation

is therefore 28 * 7 = 196W. This means that the four final transistors do most

of the work, with the others having a relatively restful time.

Since I like to be conservative, I will assume

that they contribute no more than about 1.5A (which is about right). This means

that they only dissipate 48W, with the main O/P devices dissipating a peak of

74W each. The specified transistors are 130W, and the alternatives are 150W, so

where is the problem?

The problem is simple - the

rated dissipation for a transistor is with a case temperature of 25oC.

As the amp is used, the case gets hot, and the standard derating curves should

be applied. Add to this the reactive component as the loudspeaker drives

current back into the amp, and it becomes all to easy to exceed the device

dissipation limits.

Figure 1a - Double Output Stage

Figure 1A shows the doubled output stage, with

Q9, Q10, Q11 and Q12 simply repeated - along with the emitter resistors. Each

1/2 stage has its own zobel network and bypass caps as shown, as this is the

arrangement if the dual PCB version is built. When you have this many power

transistors, the amp will happily drive a 4 ohm load all day - with a big enough

heatsink, and / or forced cooling (highly recommended, by the way).

A Few Specs and Measurements

The following figures are all relative to an output power of 225W into 4 ohms,

or 30V RMS at 1kHz, unless otherwise stated. Noise and distortion figures are

unweighted, and are measured at full bandwidth. Measurements were taken using a

300VA transformer, with 6,800uF filter caps.

Mains voltage was about 4% low when I did the

tests, so power output will normally be slightly higher than shown here if the

mains are at the correct nominal voltage.

| Gain |

27dB |

| Power (Continuous) |

240W (4 ohms) |

| |

153W (8 ohms) |

| Peak Power - 5 ms |

185W (8 ohms) |

| Peak Power - 10 ms........ |

172W (8 ohms) |

| Input Voltage |

1.3V |

| Noise |

-63dBV (ref. 1V) |

| S/N Ratio |

92dB |

| Distortion |

0.4% |

| Distortion (@ 4W) |

0.04% (1 Khz) |

| Distortion (@ 4W) |

0.07% (10 kHz) |

| Slew Rate |

> 3V/us |

| Power Bandwidth |

30 kHz |

These figures are quite respectable, especially

considering the design intent for this amp. While it would not be really

suitable for normal hi-fi, even there it is doubtful that any deficiencies would

be readily apparent, except perhaps at frequencies above 10kHz. While the amp

is certainly fast enough (and yes, 3V/us actually is fast enough - full power is

available up to 30kHz), the distortion will be a bit too high.

Note that the "peak power" ratings represent

the maximum power before the filter caps discharge and the supply voltage

collapses. I measured these at 5 milliseconds and 10 milliseconds. Performance

into 4 ohm loads will not be quite as good, as the caps will discharge faster.

The supply voltage with zero power measured exactly 56V, and collapsed to 50.7V

at full power into 8 ohms, and 47.5V at full power into 4 ohms.

Power Supply

|

WARNING: Mains wiring must be performed by a qualified electrician - Do not

attempt the power supply unless suitably qualified. Faulty or incorrect

mains wiring may result in death or serious injury. |

The basic power supply is shown

in Figure 2. It is completely conventional in all respects. Use a 40-0-40 V

transformer, rated at 300VA for normal use. For maximum continuous power, a

500VA or bigger transformer will be needed. This will give a continuous power

of about 350W, and peak power of close to 400W is possible with a good

transformer. Remember my warnings about using the amp in this way, and the need

for the additional output transistors.

Figure 2 - Basic Power Supply Circuit

For 115V countries, the fuse should be 6A, and

in all cases a slow blow fuse is required because of the inrush current of the

transformer.

C1 must be rated for 240V AC (or 120V AC)

operation - do not use standard 250V DC caps under any circumstance, as they

will fail, and R1 will explode! This is not intended as humour - this is fact!

C1 and R1 may be omitted in most cases, and if you cannot get a mains rated

capacitor I suggest that you don't install these components.

The supply voltage can be expected to be higher

than that quoted at no load, and less at full load. This is entirely normal, and

is due to the regulation of the transformer. In some cases, it will not be

possible to obtain the rated power if the transformer is not adequately rated.

Bridge rectifiers should be 35A types, and

filter capacitors must be rated at a minimum of 63V. Wiring needs to be heavy

gauge, and the DC must be taken from the capacitors - not from the bridge

rectifier.

Although shown with 4,700uF filter capacitors,

larger ones may be used. Anything beyond 10,000uF is too expensive, and will

not improve performance to any worthwhile degree. Probably the best is to use

two 4,700uF caps per side (four in all). This will actually work better than a

single 10,000uF device, and will be cheaper as well.

NOTE: It

is essential that fuses are used for the power supply. While they will not stop

the amp from failing (no fuse ever does), they will prevent catastrophic damage

that would result from not protecting the circuit from over-current conditions.

Fuses can be mounted in fuseholders or can be inline types. The latter are

preferred, as the supply leads can be kept as short as possible. Access from

outside the chassis is not needed - if the fuses blow, the amplifier is almost

certainly damaged.

What Does It Look Like?

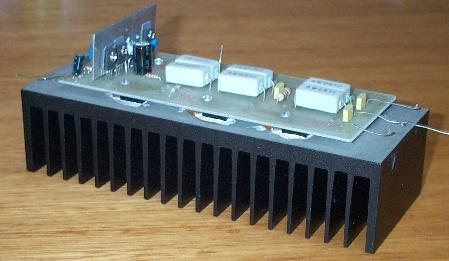

I have included a photo of the

prototype amp, fully mounted on its heatsink. For normal use, some brackets

would also be needed to mount the heatsink, unless two assemblies were used as

the side panels of a conventional (stereo) amplifier chassis.

Figure 3 - Completed Amp Module

As can be seen, this is the single board

version. The driver transistors are in a row, so that a single sheet aluminium

heatsink can be used for all three. Holes are provided on the board so the

driver heatsink can be mounted firmly, to prevent the transistor leads breaking

due to vibration. This is especially important if the amp is used for a powered

subwoofer, but will probably not be needed for a chassis mounted system.

The driver and main heatsinks shown are

adequate for up to 200W into 4 ohms with normal program material. The bits of

wire you can see were used for hooking the amp up to a test supply for the

measurements and listening tests. The power transistors are all mounted

underneath the board, and the mounting screw heads can be seen on the top of the

board.

Deceptively simple, isn't it?

Дата публикации: 2004-02-26

Прочтено: 35004

Версия для печати:  |

Главная

Главная

Схемы

Схемы

Студентам

Студентам

Программы

Программы

Поиск

Поиск

Top50

Top50

Главная

Главная

Схемы

Схемы

Студентам

Студентам

Программы

Программы

Поиск

Поиск

Top50

Top50